History

"This is the story of Stony Ridge Observatory, the result of a lot of blood, sweat and tears of the part of fifteen amateur astronomers who didn't know what they were getting into..."

as quoted in “Stony Ridge Observatory, Inc. – A Cooperative Effort”

Norris A. Roberts

Stony-Ridge Observatory

"This is the story of Stony Ridge Observatory, the result of a lot of blood, sweat and tears on the part of fifteen amateur astronomers who didn't know what they were getting into..."

as quoted in “Stony Ridge Observatory, Inc. – A Cooperative Effort”

Norris A. Roberts

Stony-Ridge Observatory

The Stony Ridge Story

Documenting the Journey

The founding of Stony Ridge Observatory is testament to inspiration, teamwork, and a single-minded dedication to seeing astronomical aspirations become both tangible and long-lasting. On this page is a chronology and fascinating visual telling which detailis some of the highlights of that journey. Taken together, a richly detailed story emerges, each accounting like a rung in a literal climb to the stars.

The experiences related here provide a sense of the challenges as faced firsthand by the founders and culminates with the exhilaration of seeing First Light, a time-honored celebration which christens the birth of any new telescope and especially one brought forth through such a long and difficult labor.

Filming a Founding

Dr. H. W. Griffith, an original member of Stony Ridge Observatory team, recorded some of the group’s activities during that slow but steady ascent. Although an amateur creation, the movie had the flavor of an early motion picture, silent but embedded with subtitles befitting a professional production.

The original footage has been digitized and is available via YouTube links embedded in the photographs below or the titles beneath them.

Chapter 1 - Foundations

Designs for a new telescope; mirror preparation; site development

Chapter 2 - Fabrication

Building a telescope and mount, then figuring out how to house them

Chapter 3 - Assembly

Putting the pieces together and seeing light at the end of a 30-inch tunnel

Chronology

1947

A group of amateur astronomers, including George A. Carroll, Ernest R. Siefkin, and Jerome B. White formed The Association of Amateur Astronomers (AAA) for the purpose of:

- Engaging in the study of the history and science of Astronomy and Astrophysics

- Operating a nonprofit organization holding scientific meetings, and conducting research projects

- Assisting in the dissemination of scientific knowledge pertaining to Astronomy and Astrophysics

February 1957

The AAA membership, now numbering about 15 individuals, each pledge their time and resources to the completion of an observatory that will house a major instrument for the benefit of amateur astronomy.

An Executive Committee (EC) forms with responsibilty for various aspects of the facility’s design and construction. The committee is charged with authorization to call on any one of the members for aid, information, or whatever assistance is needed to carry out its duties.

The first EC consists of:

- Ernest (Easy) Sloman

Chairman

- George A. Carroll

Chief Engineer

- Eugene C. Larr

Optical Engineer

- Alan McClure

Expediter

The other members of the AAA fan out into these divisions. They perform under and are accountable to, the respective EC officer in charge.

It Starts Here

This is an artist's conception of the 30-inch telescope that would become the centerpiece of the Stony Ridge Observatory complex. Completing it would be a catalyst to fuel the rest of the project.

As with any large, precision instrument, the final design would take considerable and painstaking effort to coalesce. Many coordinated decisions would be made to bring it and SRO into existence.

Who was the artist?? Perhaps George Carroll, judging from the snippet of information in the lower right-hand corner!

The group reasons that by focusing on the telescope first, the completed, or nearly-completed apparatus will demonstrate credibility for successful completion of the entire project.

Thus, the telescope will serve as a beacon to attract new persons (and funds) to the membership, giving additional supporters justification to invest in the endeavor. This initial insight will later prove to be a most pivotal decision.

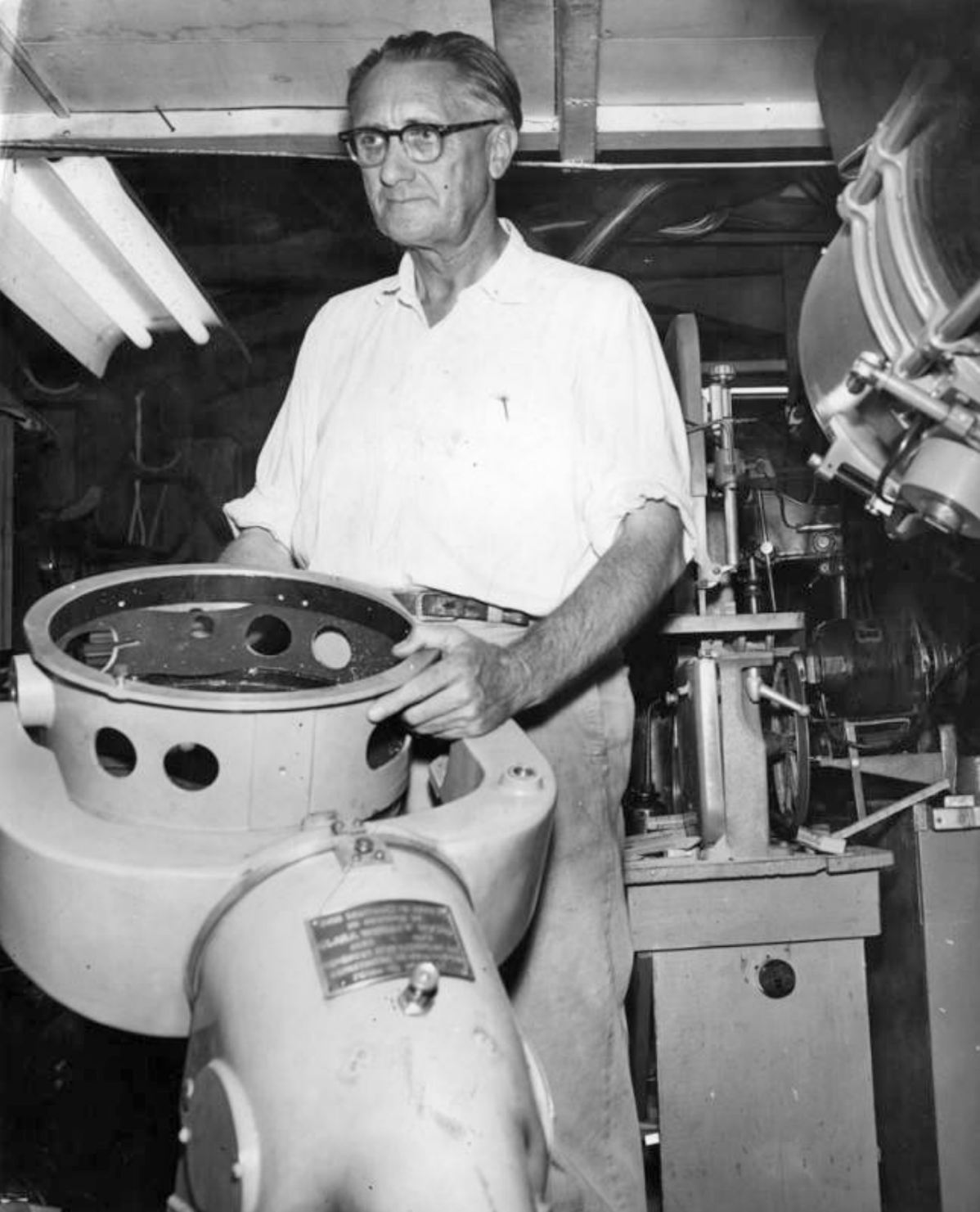

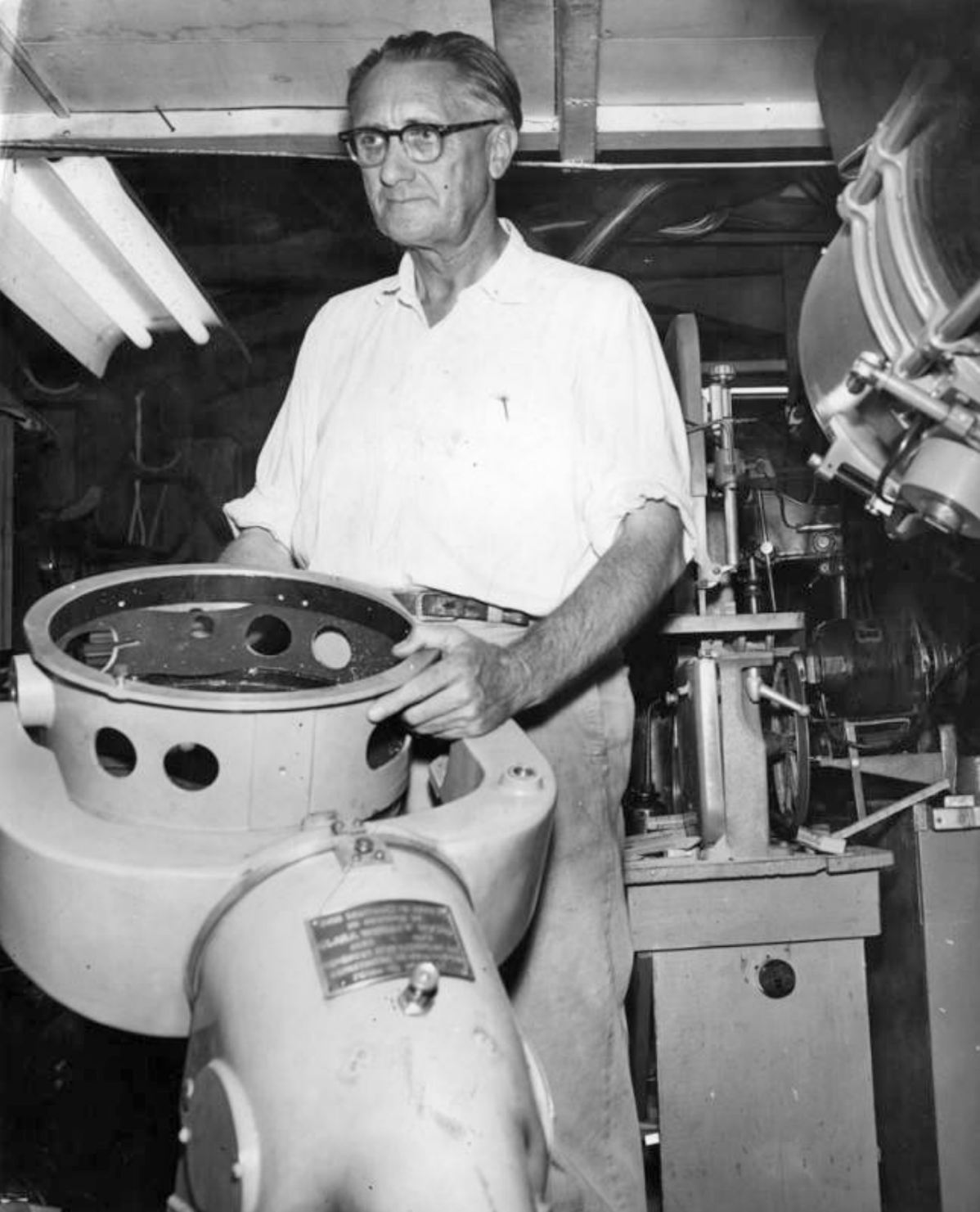

Designated Designer

It was up to George Carroll to conceive the telescope and get it built. He closely oversaw all aspects of its construction as a hands-on technician.

This photo was taken in 1956, just before commencement of the Stony Ridge project.

Los Angeles Public Library,

Valley Times Photo Archives

April 1957

After obtaining advice from Dr. Ira Bowen, Director of the Mt. Wilson Observatory, and Don Hendrix, chief optician responsible for the final polishing of the Hale telescope’s 200-inch objective, Gene Larr suggests to the EC that a mirror 30-40 inches in diameter and operating at a focal ratio of f/6 would be an appropriate design specification for the new telescope.

Larr also has discussions with Bowen about situating the observatory somewhere on the grounds of the Mt. Wilson Observatory. Although initially accepting of the idea, the Director ultimately declines citing issues with insurance.

Some of Larr’s friends and a few professional astronomer acquaintances express an interest in joining the group. Among them is noted Mt. Wilson/Palomar astronomer Allan Sandage, though in the end, he does not become a member of either the AAA or SRO.

Estimates for mirror blanks of the suggested size are obtained from the Corning Glass Works in Pennsylvania. Additionally, an obsidian mirror blank is available for sale at Tinsley Labs in northern California and is briefly discussed but rejected after learning of numerous near-surface bubbles that will require extra work to remove during grinding. Finally, an order is placed with Corning to cast a 30.5-inch pyrex glass at a cost of $1425.

The design and construction of the telescope becomes the responsibility of George A. Carroll (1902-1987), a pioneer aircraft designer and a well-known instrument and telescope maker in Southern California.

With the cost of the primary mirror now known, Carroll estimates the total outlay for the telescope to be $7500, or about $500 per member. It is decided to increase the $5/month membership fee to $10 to help finance that expense over a four year period.

May 1957

Members not directly focused on the design and construction of the telescope involve themselves with other concerns of the project. The selection of a suitable observatory site is being pursued by Easy Sloman.

On the short list is a 160-acre plot privately owned by a friend of his near Chilao Flats in the Angeles National Forest that might be available for lease, at a cost of about $400/yr. However, 160 acres is certainly much more area than needed for the observatory. Representatives with the US Forest Service (USFS) indicate to Sloman that a lease for $100/year could probably be made through a “Special Use Permit” for USFS land that would satisfy project needs.

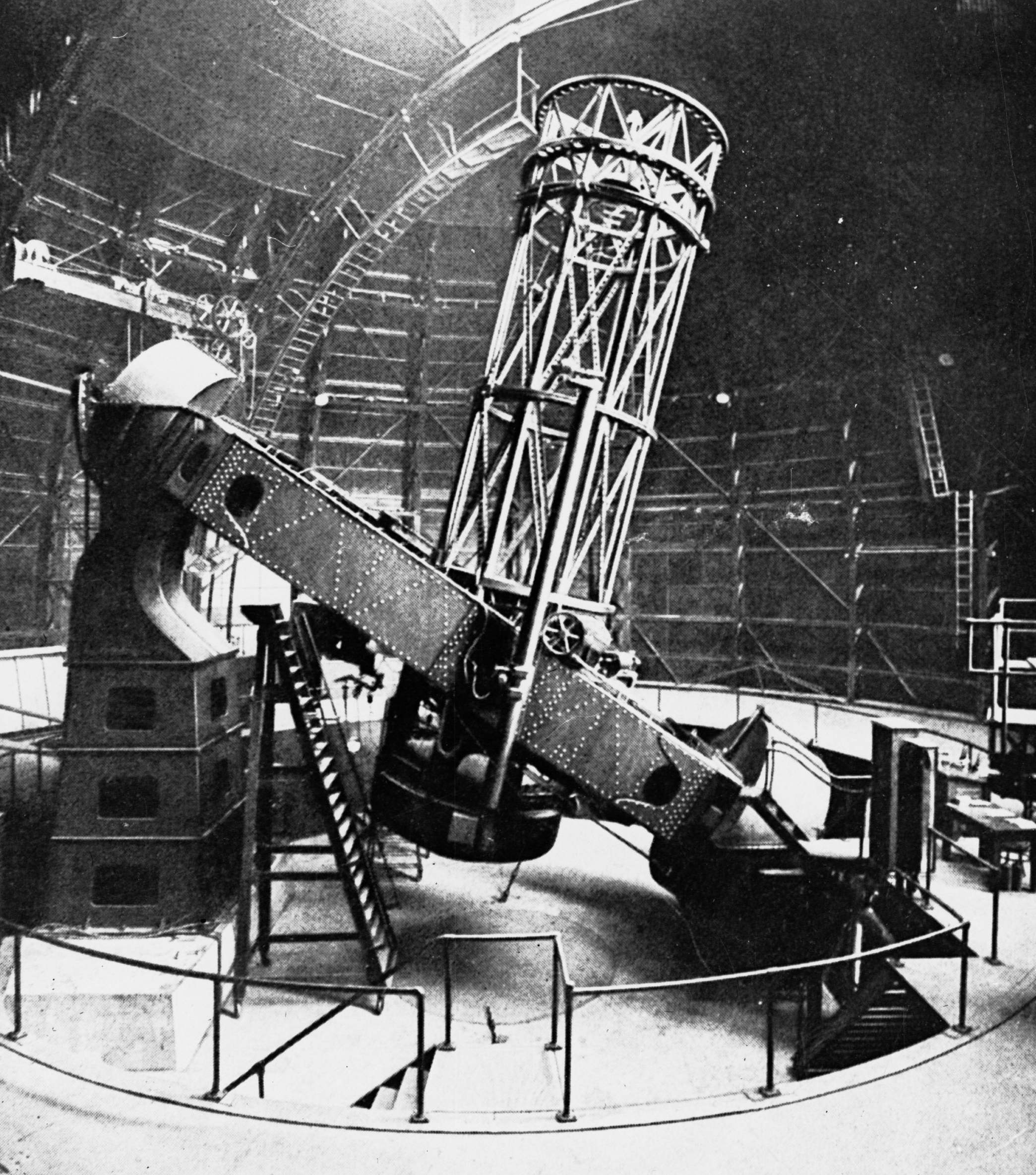

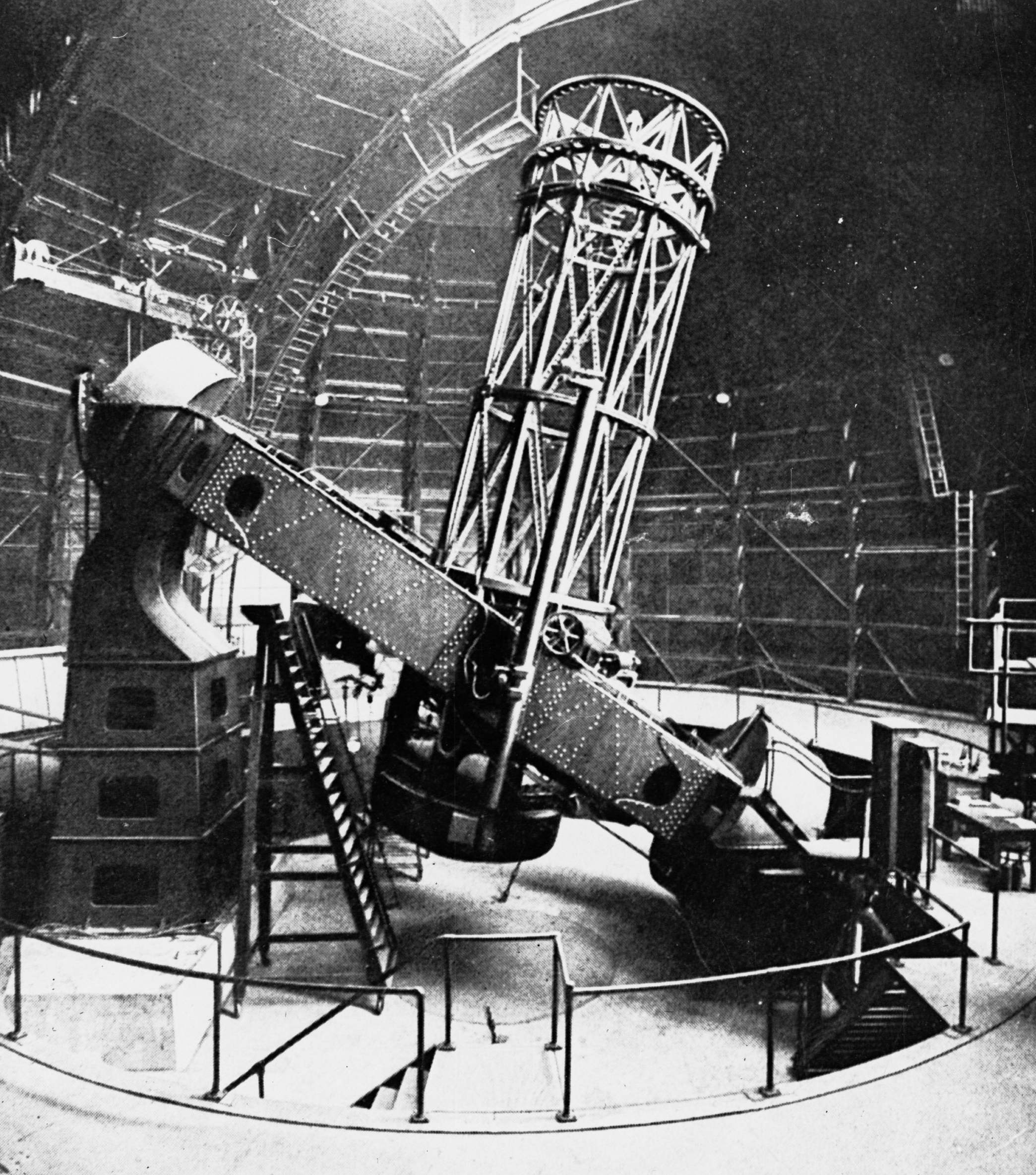

We're Not Yoking

In an effort to trim costs, the suitability of an English Yoke mount was explored, a type similar to this one used for the 100-inch Hooker telescope at Mt. Wilson Observatory. But this design, while less complex than others, is far from ideal.

Not only does this mount's yoke implementation limit access to the most northerly parts of the sky (at left), but two large piers, and the massive footings required to anchor each one, could dicatate a larger enclosure. These and other negative implications effectively undermine some of the economies it promises.

“The One Hundred Inch Hooker Telescope

Mt Wilson Observatory, California

(GN03572).jpg”

by State Government Photographer

(licensed under CC BY 2.0)

June 1957

Carroll suggests his $7500 telescope estimate is probably too high.

An English mount, similar to that for the 100-inch telescope at Mt. Wilson is proposed under the premise that such a support saves 30% of the cost of a fork mount.

The fork mount, for reasons of operational convenience, is chosen nevertheless.

This is Home

It didn't take an Act of Congress to secure this site, but the act of a congressman sure did help. That bit of legislative push removed one of the last hurdles in obtaining the lease granting use of the land.

Grading had already been accomplished when this shot was made. The view is to the southeast.

January 1958

Because of delays and perceptions of shady negotiations by Corning, the EC cancels its order. It decides to purchase a 30-inch mirror blank from the Hayward Scientific Company in Whittier, CA.

April 1958

The Hayward blank arrives 2 inches too thick. After assessing the glass and declaring it unacceptable, Larr rejects the blank and instructs Hayward to re-cast another, this one to the agreed upon specifications.

May 1958

After a thorough investigation of possible observatory sites, a location in the Angeles National Forest – near Charlton Flats – is selected. It is favored because it is reasonably near the members and because of proximity to Mt Wilson, known for historically good astronomical seeing.

After some intervention by the district’s congressional representative, an application for a “Special Use Permit” is filed with USFS.

A complication then arises… the California Transportation Department (Cal Trans) will not spend public funds on construction of a private road to the observatory site, especially one about 4000 feet off the highway. Another snag: the County of Los Angeles has never before issued a new building permit for an observatory on a remote mountain top!

Eventually, a trilateral agreement is reached regarding the road. Some of the work will be paid for by the County of LA, some by the USFS, and the rest assumed by the SRO membership, the later through a contractor engaged to perform the work.

September 1958

Carroll reports that the design for the telescope is finalized and that George Perkins will draft the engineering drawings. Next, the search ensues for a fabricator to manufacture the polar axis and fork mount.

Carroll suggests a truncated cone structure for the dome, similar to the housing for the 24-inch telescope at Lowell Observatory. Larr similarly recommends wood for the structural material and sheathing, noting excellent reports from Lowell’s experience.

An opposing opinion is voiced by Norrie Roberts, in charge of all the buildings at the site. He feels that a hemispherical dome, made from steel supports and clad with an aluminum skin, would be more desirable. After much discussion, the Roberts proposal, though more expensive, prevails.

That turned out to be a fortuitous decision when, in 2009, the “Station” fire swept over the observatory site – from 2 directions! – yet without permanent damage to any of the facilities. A wooden dome, as originally envisioned, might have been easily sparked by an ember and consumed, to say nothing of the invaluable contents inside.

Larr states that rough grinding of the 30-inch mirror has commenced at his shop in Altadena, CA using a temporary grinding machine.

USFS is still working on the fine print of the “Special Use Permit.”

"Wood" they?...

Telescope enclosures are as varied as the scopes themselves. A wooden edifice, conical and faceted like this one at Flagstaff's Lowell Observatory, was discussed but rejected in favor of a more traditional design and material.

Years later their choice would prove to be quite providential.

“Clark Telescope, Lowell Observatory”

by brewbooks

licensed under CC BY-SA 2.0

November 1958

George Carroll presents completed drawings of 30-inch, and responsibilities for building its components are assigned to various members.

He jumpstarts this phase by mentioning his find of a machine shop in Burbank. Rene Corporation, owned by John Terlep, will accommodate fabrication of the mount/fork parts.

January 1959

Carroll reports further on the Rene arrangement: Terlep is willing to give AAA members space and access – at no cost! – to all machines for creating the mount. Terlep joins AAA.

Norrie Roberts, Chuck Buzzetti and John Terlep draw up plans for the observatory’s support buildings and the dome. These are submitted for county approval, enabling construction permits to be issued.

What Does 400 Pounds of Glass Look Like?

The massive blank finally arrived after earlier setbacks. Before Larr could begin to work the glass, he had to be sure that surface defects would be shallow enough so that grinding the mirror's parabolic surface would remove them.

February 1959

The USFS Special Use Permit is approved – 11 months after the application was submitted.

Alan McClure leaves the membership to work on his own 24-inch telescope project.

Roy Ensign notifies the group that work on the new grinding table is completed.

Construction work begins on the new observatory. One of the founding members, Dr. W. H. Griffith, starts documentary filming of the group’s progress. This leads to the eventual production of a finished motion picture.

March 1960

An Amendment to the AAA’s Articles of Incorporation is filed. A new name is chosen along with the creation of a not-for-profit organization. The Stony Ridge Observatory, Inc. – SRO is officially an entity. (“Stony Ridge” was suggested by Easy Sloman.)

June 1961

For reasons unknown, Eugene Larr (1927-2006), Chief Optician, ‘disappears’ from the group. Many attempts to contact him have proven unsuccessful and it becomes necessary for the SRO Board to find a replacement for this essential member who had, hetetofore, played such an integral role from the project’s inception.

Roy K. Ensign assumes the duties of Optical Engineer and the responsibities for the ongoing mirror grinding and figuring. Since Ensign is principally involved already, the transition is appreciably easier.

A bit of internet sleuthing suggests that Gene Larr experienced an epiphany after contacts with a minister of a church next door to his Altadena shop.

According to that account, in 1973 Larr became the first Minister and co-founder of the Chapel of Awareness Spiritualist Church in Encinitas, California. He also continued his astronomy and telescope building interests by teaching amateur telescope making, and doing presentations for an amateur astronomy group in the San Diego area.

Making a Mirror from Scratch(es)

Roy Ensign devised and built this machine specifically for fashioning the 30-inch primary. Mirror grinding consists of numerous stages of programmed erosion featuring progressively finer abrasives, each step removing larger scratches made by the previous step by replacing them with smaller scratches in the current one.

For most of the process, a circular "tool" pushes the grit into the large blank, scratching it innumerable times and removing tiny amounts of the surface with each gouge. It does so while spinning and translating as the blank rotates independently underneath. Such complex motion seems imprecise but by factoring in the tool's length of oscillation - its "stroke," its applied pressure, and the amount by which it might overhang the blank, a "coordinated and prescribed randomness" yields

symmetric, controlled dishing.

Initially, Ensign's cast iron disc rubbed chunkish bits of crushed steel into the blank with the goal of rapidly generating a rough, spherical surface. Further stages used less and less grittier powders (suspended in water) to refine the rounded profile until the curve was perfectly spherical and highly polished. Then begins the process of easing the mirror's face into the shape of a parabola - a necessary transformation for optimal performance.

By the end of a mirror's final figuring, a process of fine-tuning that parabolic shape, it's possible that an optician will use only their thumb and a slurry of fine rouge to target individual spots needing the slightest bit of correction. Quantifying such minute coaxing is revealed by sensitive tests of reflected light that can highlight imperfections measured in millionths of an inch.

How much glass was removed in figuring the mirror's surface? The deepest part of the concave face is a little less than 1/3 of an inch below the rim.

March 1963

Roy Ensign announces that mirror preparation is finished.

He has tested the cross-sectional shape of its front surface (its “figure”) and measured its deviation from the desired geometric specification. Using the standard, but sub-microscopic unit of measure, one wavelength of light, his mirror deviates from a perfect parabola by “1/35 wave” – 59 millions of an inch – an astounding precision.

To be ready for use, the mirror lacks only an aluminized face and protective overcoating.

John Terlep reports that Norm Bolz has nearly completed installation of the dome rotation system at the site.

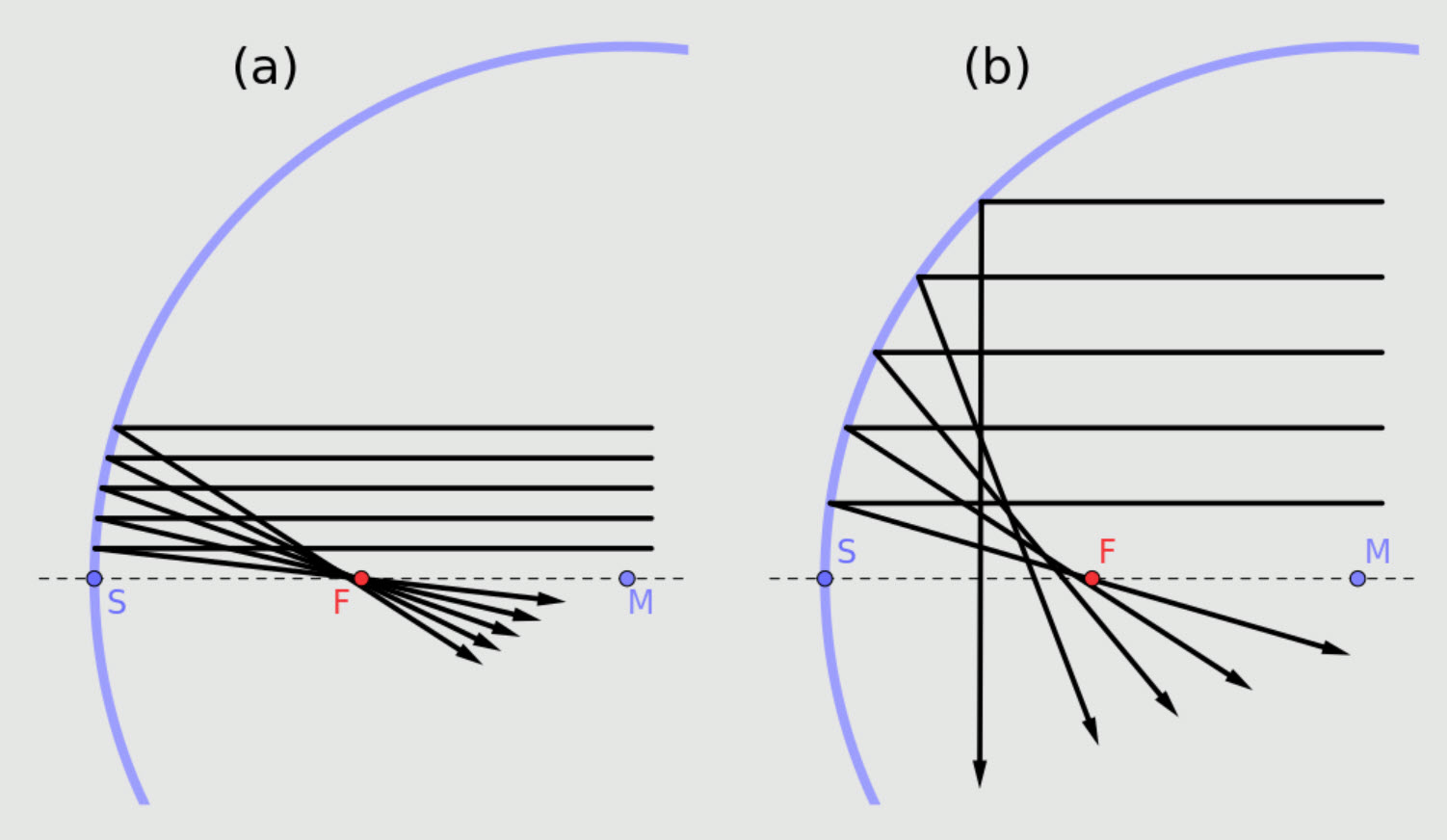

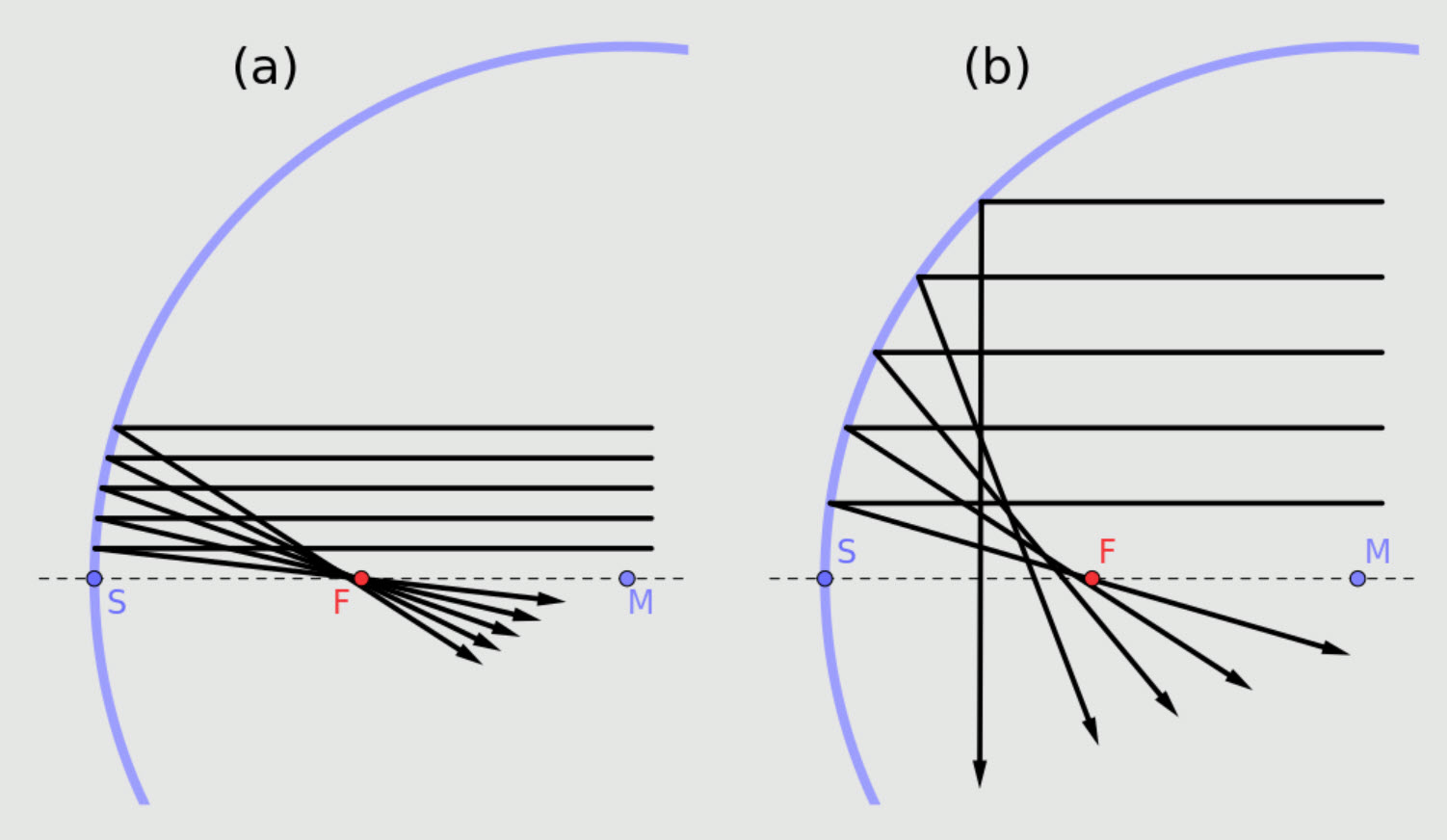

Why a Parabolic Surface?

You might logically imagine that a telescope mirror's surface ought to be spherical. In other words, if on the mirror you rested a ball of matching curvature, the two surfaces would touch at every point on the glass. If so, you'd further conclude that all the light rays hitting the mirror would focus where the center of the ball is. But, due to the laws of reflection - and a little algebra - that's NOT how it works!

For a spherical mirror, the point of focus (F) depends upon the radial distance of the incident ray. This is shown in drawing (b) above.

A parabolic surface, on the other hand, provides a reflection in which all the rays focus at a common point as illustrated in (a). This curvature profile is the usual design goal for reflecting telescopes like the 30-inch at SRO.

The deeply sloped surface parabola of a short-focus reflector is very had to produce; the one on the Carroll telescope's mirror only moderately so. For very long focus reflectors, the difference between a parabola and a sphere is quite negligible and many opticians won't bother with even trying to parabolize.

If you're thinking "why not just make all reflectors long-focus?" and skip a step, you have to realize that the optical and mechanical properties of such mirrors are aren't widely desireable. These optics provide a very narrow field of view, are"slow" photographically leading to longer exposures, and they place greater structural and facility demands on the tube (longer), mount (more massive) and observatory structure (larger), to name but a few.

MikeRun

CC BY-SA 4.0 via Wikimedia Commons

Spring/Summer 1963

Despite the uplifting news about the mirror – the heart of the project – there are grave concerns about the entirety of everything else needed to put it into service. In short, funds are perilously low and the membership is thoroughly tapped out. Just how dire are things??

There is about $400 in the bank to cover $1400 in debts and this represents the state of affairs after all previous infusions of cash ponied up by the SRO, Inc. investor – astronomers to say nothing of the additional outlays that will be required in order to finish.

If this doesn’t seem so bad, consider the equivalent value in today’s (2024) dollars: $4100 and $14,400.

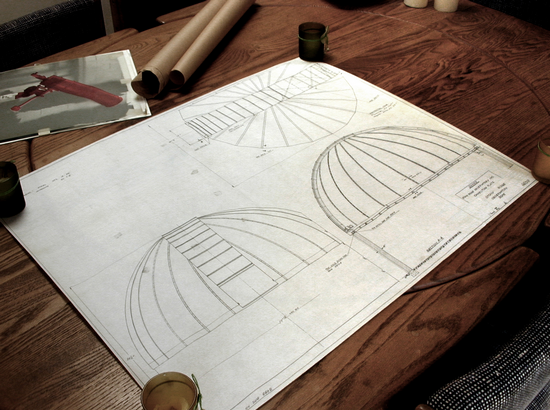

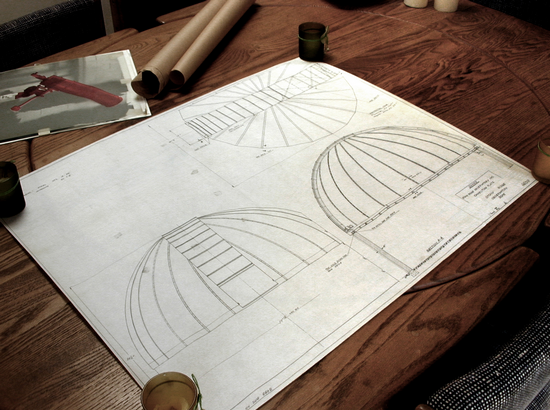

Dome Home

Efficient dome design can only be accomplished when the dimensions of the telescope are known, primarily in terms of ensuring the tube and the hemisphere will not touch in any orientation of either. The interior of the SRO dome has ribs which support the aluminum skin and protrude inward, a further complication.

At Stony Ridge, the clearance is very tight, a direct result of an optimized dome design which minimizes the 2-D circular footprint and the exponential 3-D cost that follows. Another important logistical consideration is keeping the structure transportable for the one-time trip up the mountain.

All in all, the squeeze means that astronomers must be vigilant when moving the telescope (or the dome) because a third essential component is in the mix, the tallish scissor lift used to reach the Newtonian focus. Nobody wants to be guilty of allowing precious things to go "bump in the night," especially those so carefully fashioned and exceedingly difficult to repair.

Michael Madsen (from the estate of John Terlep)

In fact, prospects for completion of the observatory are of great concern to everybody. Here’s but one example…

The most expensive piece of the project is the steel and aluminum dome. Nearing completion at Thomas Tool & Die Company in Sun Valley, the two halves will still need trucking up to the site and require a crane to install them atop the waiting observatory walls.

There are additional costs everywhere they look.

August 1963

Roy Ensign advises that the mirror is at the Mt. Wilson Observatory being aluminized.

At this meeting, the members celebrate a “‘first’ First Light” for the facility, enjoying views of Saturn through the 6-inch guide scope.

September 1963

The observatory is finished and at long last, “First-Light” is beaming through the Stony Ridge reflector.

Upon completion, this superb 30-inch telescope is the eighth largest in California. It may well be the largest amateur telescope in the world.

One Mission Complete, Another One Starts

The Stony-Ridge Observatory's

30-inch (.76m) Newtonian-Cassegrain Reflecting Telescope

c1964.

1947

A group of amateur astronomers, including George A. Carroll, Ernest R. Siefkin, and Jerome B. White form “The Association of Amateur Astronomers” (AAA) for the purpose of:

- Engaging in studies regarding the history and science of Astronomy and Astrophysics

- Operating a nonprofit organization which holds scientific meetings, and conducts research projects

- Assisting in the dissemination of scientific knowledge pertaining to Astronomy and Astrophysics

February 1957

The AAA membership, now numbering about 15 individuals, each pledge their time and resources to the completion of an observatory that will house a major instrument for the benefit of amateur astronomy.

An Executive Committee (EC) asssembles with responsibilty for various aspects of the facility’s design and construction. The committee is charged with authorization to call on any one of the members for aid, information, or whatever assistance is needed to carry out its duties.

- Ernest (Easy) Sloman – Chairman

- George A. Carroll – Chief Engineer

- Eugene C. Larr – Optical Engineer

- Alan McClure – Expediter

The other members of the AAA fan out into these divisions. They perform under and are accountable to, the respective EC officer in charge.

It Starts Here

This is an artist's conception of the 30-inch telescope that would become the centerpiece of the Stony Ridge Observatory complex. Completing it would be a catalyst to fuel the rest of the project.

As with any large, precision instrument, the final design would take considerable and painstaking effort to coalesce. Many coordinated decisions would be made to bring it and SRO into existence.

Who was the artist?? Perhaps George Carroll, judging from the snippet of information in the lower right-hand corner!

The group reasons that by focusing on the telescope first, the completed, or nearly-completed apparatus will demonstrate credibility for successful completion of the entire project.

Thus, the telescope will serve as a beacon to attract new persons (and funds) to the membership, giving additional supporters justification to invest in the endeavor. This initial insight will later prove to be a most pivotal decision.

Designated Designer

It was up to George Carroll to conceive the telescope and get it built. He closely oversaw all aspects of its construction as a hands-on technician.

This photo was taken in 1956, just before commencement of the Stony Ridge project.

Los Angeles Public Library,

Valley Times Photo Archives

April 1957

After obtaining advice from Dr. Ira Bowen, Director of the Mt. Wilson Observatory, and Don Hendrix, chief optician responsible for the final polishing of the Hale telescope’s 200-inch objective, Gene Larr suggests to the EC that a mirror 30-40 inches in diameter and operating at a focal ratio of f/6 would be an appropriate design specification for the new telescope.

Larr also has discussions with Bowen about situating the observatory somewhere on the grounds of the Mt. Wilson Observatory. Although initially accepting of the idea, the Director ultimately declines citing issues with insurance.

Some of Larr’s friends and a few professional astronomer acquaintances express an interest in joining the group. Among them is noted Mt. Wilson/Palomar astronomer Allan Sandage, though in the end, he does not become a member of either the AAA or SRO.

Estimates for mirror blanks of the suggested size are obtained from the Corning Glass Works in Pennsylvania. Additionally, an obsidian mirror blank is available for sale at Tinsley Labs in northern California and is briefly discussed but rejected after learning of numerous near-surface bubbles that will require extra work to remove during grinding. Finally, an order is placed with Corning to cast a 30.5-inch pyrex glass at a cost of $1425.

The design and construction of the telescope becomes the primary responsibility of George A. Carroll (1902-1987), a pioneer aircraft designer and a well-known instrument and telescope maker in Southern California.

With the cost of the primary mirror now known, Carroll estimates the total outlay for the telescope to be $7500, or about $500 per member. It is decided to increase the $5/month membership fee to $10 to help finance that expense over a four year period.

May 1957

Members not directly involved with the design and construction of the telescope busy themselves with other concerns of the project. Selection of a suitable observatory site is pursued by Easy Sloman.

On the short list of possibilities is a 160-acre plot near Chilao Flats within the Angeles National Forest. It is privately owned by a friend and might available for lease at about $400/yr.

Whatever enthusiasm this generates is tempered by the sheer size of the parcel. Entities with the US Forest Service (USFS) present another potential solution, this for a $100 lease through a “Special Use Permit” on a much more manageable plot.

We're Not Yoking

In an effort to trim costs, the suitability of an English Yoke mount was explored, a type similar to this one used for the 100-inch Hooker telescope at Mt. Wilson Observatory. But this design, while less complex than others, is far from ideal.

Not only does this mount's yoke implementation limit access to the most northerly parts of the sky (at left), but two large piers, and the massive footings required to anchor each one, could dicatate a larger enclosure. These and other negative implications effectively undermine some of the economies it promises.

“The One Hundred Inch Hooker Telescope

Mt Wilson Observatory, California(GN03572).jpg”

by State Government Photographer

licensed under CC BY 2.0

June 1957

Carroll suggests his $7500 telescope estimate is probably too high.

An English mount, similar to that for the 100-inch telescope at Mt. Wilson is proposed under the premise that such support saves 30% of the cost of a fork mount. The fork mount, for reasons of operational convenience, is chosen nevertheless.

This is Home

It didn't take an Act of Congress to secure this site, but the act of a congressman sure did help. That bit of legislative push removed one of the last hurdles in obtaining the lease granting use of the land.

Grading had already been accomplished when this shot was made. The view is to the southeast.

January 1958

Because of delays and perceptions of shady negotiations by Corning, the EC cancels its order. It decides to purchase a 30-inch mirror blank from the Hayward Scientific Company in Whittier, CA.

April 1958

The Hayward blank arrives 2 inches too thick. After assessing the glass and declaring it unacceptable, Larr rejects the blank and instructs Hayward to re-cast another, this one to the agreed upon specifications.

May 1958

After a thorough investigation of possible observatory sites, a location in the Angeles National Forest – near Charlton Flats – is selected. It is favored because it is reasonably near the members and because of proximity to Mt Wilson, known for historically good astronomical seeing.

After some intervention by the district’s congressional representative, an application for a “Special Use Permit” is filed with USFS.

A complication then arises… the California Transportation Department (Cal Trans) will not spend public funds on construction of a private road to the observatory site, especially one about 4000 feet off the highway. Another snag: the County of Los Angeles has never before issued a new building permit for an observatory on a remote mountain top!

Eventually, a trilateral agreement is reached regarding the road. Some of the work will be paid for by the County of LA, some by the USFS, and the rest assumed by the SRO membership, the later through a contractor engaged to perform the work.

September 1958

Carroll reports that the design for the telescope is finalized and that George Perkins will draft the engineering drawings. Next, the search ensues for a fabricator to manufacture the polar axis and fork mount.

Carroll suggests a truncated cone structure for the dome, similar to the housing for the 24-inch telescope at Lowell Observatory. Larr similarly recommends wood for the structural material and sheathing, noting excellent reports from Lowell’s experience.

An opposing opinion is voiced by Norrie Roberts, in charge of all the buildings at the site. He feels that a hemispherical dome, made from steel supports and clad with an aluminum skin, would be more desirable. After much discussion, the Roberts proposal, though more expensive, prevails.

That turned out to be a fortuitous decision when, in 2009, the “Station” fire swept over the observatory site – from 2 directions! – yet without permanent damage to any of the facilities. A wooden dome, as originally envisioned, might have been easily sparked by an ember and consumed, to say nothing of the invaluable contents inside.

Larr states that rough grinding of the 30-inch mirror has commenced at his shop in Altadena, CA using a temporary grinding machine.

USFS is still working on the fine print of the “Special Use Permit.”

"Wood" they?...

Telescope enclosures are as varied as the scopes themselves. A wooden edifice, conical and faceted like this one at Flagstaff's Lowell Observatory, was discussed but rejected in favor of a more traditional design and material.

Years later their choice would prove to be quite providential.

“Clark Telescope, Lowell Observatory”

by brewbooks

licensed under CC BY-SA 2.0

November 1958

George Carroll presents completed drawings of 30-inch, and responsibilities for building its components are assigned to various members.

He jumpstarts this phase by mentioning his find of a machine shop in Burbank. Rene Corporation, owned by John Terlep, will accommodate fabrication of the mount/fork parts.

January 1959

Carroll reports further on the Rene arrangement: Terlep is willing to give AAA members space and access – at no cost! – to all machines for creating the mount. Terlep joins AAA.

Norrie Roberts, Chuck Buzzetti and John Terlep draw up plans for the observatory’s support buildings and the dome. These are submitted for county approval, enabling construction permits to be issued.

What Does 400 Pounds of Glass Look Like?

The massive blank finally arrived after earlier setbacks. Before Larr could begin to work the glass, he had to be sure that surface defects would be shallow enough so that grinding the mirror's parabolic surface would remove them.

February 1959

The USFS Special Use Permit is approved – 11 months after the application was submitted.

Alan McClure leaves the membership to work on his own 24-inch telescope project.

Roy Ensign notifies the group that work on the new grinding table is completed.

Construction work begins on the new observatory. One of the founding members, Dr. W. H. Griffith, starts documentary filming of the progress which eventually leads to a finished motion picture.

March 1960

An Amendment to the AAA’s Articles of Incorporation is filed. A new name is chosen along with the creation of a not-for-profit organization. The Stony Ridge Observatory, Inc. – SRO is officially an entity. (“Stony Ridge” was suggested by Easy Sloman.)

June 1961

For reasons unknown, Eugene Larr (1927-2006), Chief Optician, ‘disappears’ from the group. Many attempts to contact him have proven unsuccessful and it becomes necessary for the SRO Board to find a replacement for this essential member who had, hetetofore, played such an integral role from the project’s inception.

Roy K. Ensign assumes the duties of Optical Engineer and the responsibities for the ongoing mirror grinding and figuring. Since Ensign is principally involved already, the transition is appreciably easier.

A bit of internet sleuthing suggests that Gene Larr experienced an epiphany after contacts with a minister of a church next door to his Altadena shop.

According to that account, in 1973 Larr became the first Minister and co-founder of the Chapel of Awareness Spiritualist Church in Encinitas, California. He also continued his astronomy and telescope building interests by teaching amateur telescope making, and doing presentations for an amateur astronomy group in the San Diego area.

Making a Mirror from Scratch(es)

Roy Ensign devised and built this machine specifically for fashioning the 30-inch primary. Mirror grinding consists of numerous stages of programmed erosion featuring progressively finer abrasives, each step removing larger scratches made by the previous step by replacing them with smaller scratches in the current one.

For most of the process, a circular "tool" pushes the grit into the large blank, scratching it innumerable times and removing tiny amounts of the surface with each gouge. It does so while spinning and translating as the blank rotates independently underneath. Such complex motion seems imprecise but by factoring in the tool's length of oscillation - its "stroke," its applied pressure, and the amount by which it might overhang the blank, a "coordinated and prescribed randomness" yields

symmetric, controlled dishing.

Initially, Ensign's cast iron disc rubbed chunkish bits of crushed steel into the blank with the goal of rapidly generating a rough, spherical surface. Further stages used less and less grittier powders (suspended in water) to refine the rounded profile until the curve was perfectly spherical and highly polished. Then begins the process of easing the mirror's face into the shape of a parabola - a necessary transformation for optimal performance.

By the end of a mirror's final figuring, a process of fine-tuning that parabolic shape, it's possible that an optician will use only their thumb and a slurry of fine rouge to target individual spots needing the slightest bit of correction. Quantifying such minute coaxing is revealed by sensitive tests of reflected light that can highlight imperfections measured in millionths of an inch.

How much glass was removed in figuring the mirror's surface? The deepest part of the concave face is a little less than 1/3 of an inch below the rim.

March 1963

Roy Ensign announces that mirror preparation is finished.

He has tested the cross-sectional shape of its front surface (its “figure”) and measured its deviation from the desired geometric specification. Using the standard, but sub-microscopic unit of measure, one wavelength of light, his mirror deviates from a perfect parabola by “1/35 wave” – 59 millions of an inch – an astounding precision.

The mirror only needs an aluminized front face and protective overcoating to be ready for use.

John Terlep reports that Norm Bolz has nearly completed installation of the dome rotation system at the site.

Why a Parabolic Surface?

You might logically imagine that a telescope mirror's surface ought to be spherical. In other words, if on the mirror you rested a ball of matching curvature, the two surfaces would touch at every point on the glass. If so, you'd further conclude that all the light rays hitting the mirror would focus where the center of the ball is. But, due to the laws of reflection - and a little algebra - that's NOT how it works!

For a spherical mirror, the point of focus (F) depends upon the radial distance of the incident ray. This is shown in drawing (b) above.

A parabolic surface, on the other hand, provides a reflection in which all the rays focus at a common point as illustrated in (a). This curvature profile is the usual design goal for reflecting telescopes like the 30-inch at SRO.

The deeply sloped surface parabola of a short-focus reflector is very had to produce; the one on the Carroll telescope's mirror only moderately so. For very long focus reflectors, the difference between a parabola and a sphere is quite negligible and many opticians won't bother with even trying to parabolize.

If you're thinking "why not just make all reflectors long-focus?" and skip a step, you have to realize that the optical and mechanical properties of such mirrors are aren't widely desireable. These optics provide a very narrow field of view, are"slow" photographically leading to longer exposures, and they place greater structural and facility demands on the tube (longer), mount (more massive) and observatory structure (larger), to name but a few.

MikeRun

CC BY-SA 4.0 via Wikimedia Commons

Spring/Summer 1963

Despite the uplifting news about the mirror – the heart of the project – there are grave concerns about the entirety of everything else needed to put it into service. In short, funds are perilously low and the membership is thoroughly tapped out. Just how dire are things??

There is about $400 in the bank to cover $1400 in debts and this represents the state of affairs after all previous infusions of cash ponied up by the SRO, Inc. investor – astronomers to say nothing of the additional outlays that will be required in order to finish.

If this doesn’t seem so bad, consider the equivalent value in today’s (2024) dollars: $4100 and $14,400.

In fact, prospects for completion of the observatory are of great concern to everybody. Here’s but one example…

The most expensive piece of the project is the steel and aluminum dome. Nearing completion at Thomas Tool & Die Company in Sun Valley, the two halves will still need trucking up to the site and require a crane to install them atop the waiting observatory walls.

There are additional costs everywhere they look.

Dome Home

Efficient dome design can only be accomplished when the dimensions of the telescope are known, primarily in terms of ensuring the tube and the hemisphere will not touch in any orientation of either. The interior of the SRO dome has ribs which support the aluminum skin and protrude inward, a further complication.

At Stony Ridge the clearance is very tight, a direct result of an optimized dome design which minimizes the 2-D circular footprint and the exponential 3-D cost that follows. Another important logistical consideration is keeping the structure transportable for the one-time trip up the mountain.

All in all, the squeeze means that astronomers must be vigilant when moving the telescope (or the dome) because a third essential component is in the mix, the tallish scissor lift used to reach the Newtonian focus. Nobody wants to be guilty of allowing precious things to go "bump in the night," especially those so carefully fashioned and exceedingly difficult to repair.

Michael Madsen (from the estate of John Terlep)

The SRO project becomes the beneficiary of a particularly fortunate set of circumstances. The details are found on the Lunar Mapping page.

August 1963

Roy Ensign advises that the mirror is at the Mt. Wilson Observatory being aluminized.

At this meeting, the members celebrate a “‘first’ First Light” for the facility, enjoying views of Saturn through the 6-inch guide scope.

September 1963

The observatory is finished and at long last, “First-Light” is beaming through the Stony Ridge reflector.

Upon completion, this superb 30-inch telescope is the eighth largest in California. It may well be the largest amateur telescope in the world.

One Mission Complete, Another One Starts

The Stony-Ridge Observatory's

30-inch (.76m) Newtonian-Cassegrain Reflecting Telescope

c1964.